Gas Treatment

ABSORPTION FLUIDS FOR GAS TREATMENT

Polyethylene glycol dialkyl ethers have proved successful for scrubbing waste air and waste gas streams containing a variety of organic substances and acid gases. Clariant has developed the Genosorb™ range of absorption liquids as tailor-made solutions for many specific waste gas problems.

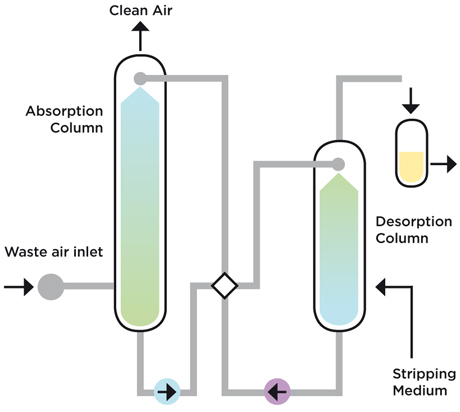

Genosorb™ absorption liquids have a low vapor pressure and low viscosity. A waste gas stream containing VOCs and/or acid gases is passed through a packed tower. The removal of VOCs and/or acid gases is achieved through the direct contact between the upward gas and the downward Genosorb™ absorption liquid. This rich Genosorb™ solution is then passed downward through a packed stripping tower.

The VOCs and/or acid gases are removed from Genosorb™ by stripping with steam or air, typically at temperatures between 70°C and 130°C, or even at low temperatures by pressure change. The resulting lean Genosorb™ solution is then passed back to the absorber column.

DESULFURIZATION OF FLUE GAS - GENOSORB™ 1900 FOR THE SOLINOX™ PROCESS

Another important application for glycol diether based absorption liquids is the Solinox™ process. The Solinox™ process was developed by Linde AG with Genosorb™ 1900 as absorption liquid.

In this process, Genosorb™ 1900 absorbs large amounts of SO2 from flue gases. The product contains a proprietary stabilizer that protects Genosorb™ against harmful effects of SO2 and SO3.

The sulfur dioxide resulting from the Solinox™ process has a very high purity and can be converted to sulfuric acid or sold as food grade quality.

Several commercial units are operating globally. The following table shows data of a Solinox™ plant based in Europe:

- Air flow: 225 000 m³/h

- SO2/SO3 inlet concentration: 20 000 mg/m³

- SO2 in cleaned gas: max. 200 mg/m³

- Sulfuric acid production: approx. 40 t/day

- Sulfur dioxide emissions are reduced by 99.9%

ABSORPTION AND RECOVERY OF VOLATILE ORGANIC COMPOUNDS

The products Genosorb™ 300 and Genosorb™ 1843 were designed for scrubbing of VOCs such as alcohols, ketones, chlorinated and fluorinated hydrocarbons, aromatics, hydrocarbons etc.

They have proved successful in around 50 installations for VOC abatement around the world. Unlike incineration or adsorption, the Genosorb™ process allows recycling of valuable organic compounds from waste gases.

Genosorb™ 1843 is a polyglycol dibutyl ether and is used to physically absorb non-polar compounds such as aromatics and hydrocarbons. Genosorb™ 1843 does not mix with water. It contains a stabilizer and tolerates acidic components in the gas stream.

Genosorb™ 300 is a polyglycol dimethyl ether and physically absorbs polar VOCs like alcohols, aldehydes etc. It is completely miscible with water. It contains a stabilizer and tolerates acidic components in the gas stream.

REMOVAL OF CO2, H2S AND TRACE COMPOUNDS FROM RAW BIOGAS

Genosorb™ 1753 effectively removes hydrogen sulfide (H2S), carbon dioxide (CO2) as well as other trace compounds from biogas to obtain natural gas (methane) that meets pipeline specifications.

The biogas resulting from fermentation of organic material contains considerable amounts of hydrogen sulfide and carbon dioxide which have to be removed before the gas can be passed to the public gas grid.

Typical commercial installations for biogas treatment comprise gas streams of 250-2 000 Nm³/h that are treated with Genosorb™ 1753.

Advances of upgrading technology with Genosorb™ 1753

- Excellent selectivity

- Low energy consumption for absorbent regeneration

- Very low methane slip

- Biogas upgrading and gas drying in one step