Partnering for success: Inside Clariant's Industrial Applications Innovation Center in North America

In today's rapidly evolving coatings, inks, and adhesives industries, formulators face increasingly complex challenges. From meeting stringent regulatory requirements to enhancing product performance while reducing environmental impact, the pressure to innovate has never been greater. At Clariant's Industrial Applications Innovation Center, located in Mount Holly, North Carolina, we've created a collaborative ecosystem where expertise, cutting-edge technology, and customer-focused solutions converge to address these challenges head-on.

Beyond the supplier relationship: true collaborative partnership

What sets Clariant apart isn't just our extensive portfolio of specialty chemicals, but our approach to customer relationships. The Industrial Applications Innovation Center embodies our commitment to being more than just a supplier – we're a dedicated innovation partner throughout the entire value chain.

"Our center was designed with one primary goal: to create a space where our technical expertise meets our customers' practical challenges," explains Pietrina Peshel, Head of Regional Application Center for BU Additives. "We don't just provide ingredients; we provide solutions developed through genuine collaboration with formulators who understand their market needs better than anyone."

State-of-the-art capabilities for coatings, inks, and adhesives to drive innovation

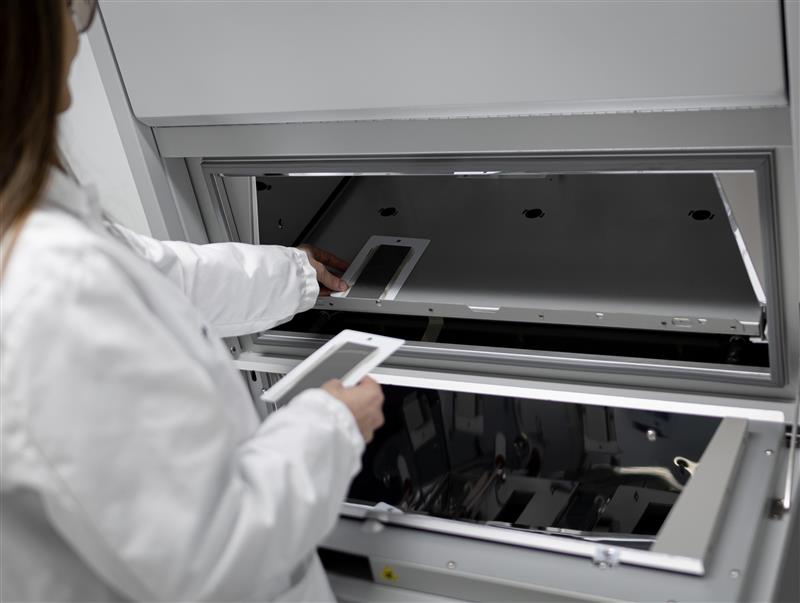

The Innovation Center houses state-of-the-art equipment and technologies specifically designed for each targeted industry. Our comprehensive facility enables us to formulate and test powder coatings, hot melt adhesives, and various other applications with precision and efficiency.

Our laboratories are equipped with specialized tools including gravure proofer, powder coating spray booths, hot melt coater laminators, and accelerating weathering equipment, to name a few. This technological foundation allows our team to simulate real-world conditions and challenges that formulators face daily, creating a bridge between laboratory innovation and practical application.

Comprehensive testing: From concept to commercialization

Understanding that thorough testing is critical to successful formulation, our center offers extensive capabilities to evaluate product performance across multiple parameters. Our testing protocols cover essential properties including:

- Ultra-violet protection efficiency and gloss retention

- Scratch and mar resistance

- Adhesion performance

- Weather resistance and color stability

- Rheological properties

- Mechanical strength and durability

These capabilities allow us to validate formulations against ASTM, ISO, and other recognized industry standards.

The collaborative development process: your challenge, our expertise

What truly distinguishes our approach is our collaborative development strategy. Rather than working in isolation, we invite customers into the innovation process from the earliest stages. This partnership model follows a structured yet flexible pathway:

- Challenge identification: We begin by thoroughly understanding the specific challenges and unmet needs formulators face in their applications.

- Solution design: Our technical experts work alongside customer teams to design potential solutions using our specialty ingredients and additives. In addition, we partner with a variety of companies to better understand the synergistic effects of our product lines.

- Iterative testing: Formulations undergo rigorous testing and refinement in our laboratories, with continuous feedback from customer partners.

- Performance validation: Final formulations are validated against industry standards and customer-specific requirements.

Specialty formulation: addressing industry-specific needs

The Innovation Center specializes in developing solutions for specific industry challenges. Our expertise spans critical formulation components including ultra-violet stabilizers, antioxidants, waxes, and specialty polymers that enhance product performance while addressing key sustainability concerns.

The collaborative development process: your challenge, our expertise

What truly distinguishes our approach is our collaborative development strategy. Rather than working in isolation, we invite customers into the innovation process from the earliest stages. This partnership model follows a structured yet flexible pathway:

- Challenge identification: We begin by thoroughly understanding the specific challenges and unmet needs formulators face in their applications.

- Solution design: Our technical experts work alongside customer teams to design potential solutions using our specialty ingredients and additives. In addition, we partner with a variety of companies to better understand the synergistic effects of our product lines.

- Iterative testing: Formulations undergo rigorous testing and refinement in our laboratories, with continuous feedback from customer partners.

- Performance validation: Final formulations are validated against industry standards and customer-specific requirements.

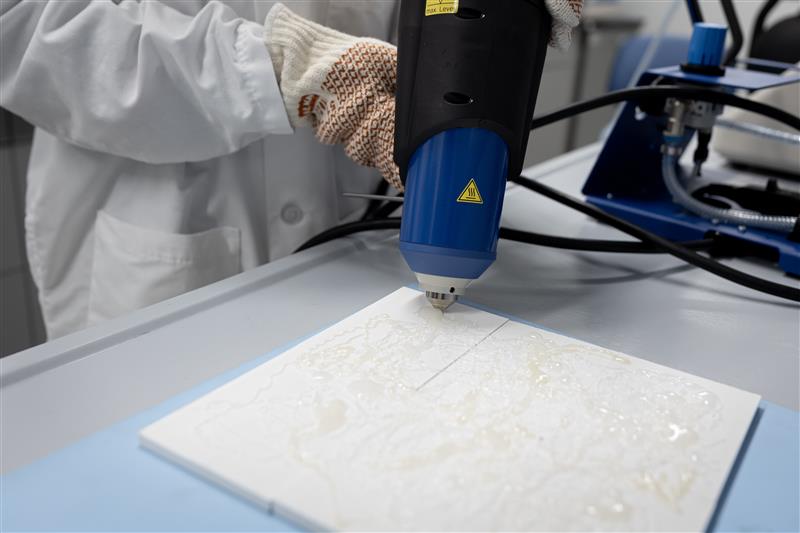

PFAS-free solutions for powder coatings formulators

For powder coating formulators, our PFAS-free solutions can improve flow, enhance surface properties, and increase durability. Our PTFE-free texturing agents delivering superior performance can help our customers realize significant cost savings.

For a circular adhesive future: combining reliable performance with renewable feedstocks

In the adhesives sector, our innovations focus on improving recyclability, bond strength, thermal stability, and application efficiency. Our certified biomass balanced-based Licocene™ Terra range includes renewable feedstock-based waxes and performance polymers that allow bonding and debonding, significantly improving the recyclability of post-industrial and post-consumer waste. Our toolbox of m-PO specialty polymers, light and heat stabilizers, and non-halogen flame retardants for adhesives and sealants address the need for more sustainable solutions paired with excellent performance.

Renewable and safer solutions for enhanced coatings performance

For liquid coatings, we develop label-free additives that improve durability, enhance weatherability, and optimize overall performance. Our water-based coating solutions feature ultra-violet stabilizer dispersions and renewable-based wax additives (e.g. rice bran waxes) that provide best-in-class weathering protection and scratch resistance. Our VITA portfolio offers 100% bio-based products, demonstrating our commitment to helping industries transition away from fossil carbon materials towards renewable carbon alternatives. These innovations address sustainability concerns by conserving energy and resources, utilizing renewable raw materials, and creating products with effective performance but less environmental impact.

Your competitive advantage: access to cutting-edge resources

For formulators, access to our Innovation Center represents a significant competitive advantage. By partnering with Clariant, companies gain:

- Access to specialized equipment and testing capabilities without major capital investment

- Technical expertise across multiple chemistry platforms

- Accelerated development timelines through collaborative problem-solving

- Insights into emerging industry trends and regulatory requirements

- Support throughout the entire product lifecycle, from concept to commercialization

A global network of expertise

With facilities strategically located in Mount Holly (USA), Knapsack (Germany), and Gersthofen (Germany), Bangkok (Thailand), and Shanghai (China), our Innovation Centers provide global support while maintaining regional expertise. This international network ensures that customers benefit from both localized knowledge and global innovation trends, regardless of their location.

"The power of our Innovation Center lies in its connectivity," notes Peshel. "We've created an environment where knowledge flows freely between our global experts and our customers' teams, accelerating the development process and ensuring solutions are tailored to specific market needs across different regions."

Building the future of specialty additives together

As the coatings, inks, and adhesives industries continue to evolve, the need for collaborative innovation becomes increasingly important. Clariant's Industrial Applications Innovation Center stands ready to partner with formulators facing complex challenges, providing not just additives, but comprehensive solutions developed through genuine collaboration.

By combining our chemical expertise with our customers' application knowledge, we create formulations that push the boundaries of performance while meeting sustainability goals. This partnership approach exemplifies our commitment to delivering greater chemistry between people and planet – creating solutions that benefit our customers, their end-users, and the environment.

Whether you're looking to enhance an existing formulation or develop an entirely new product line, our Innovation Center offers the resources, expertise, and collaborative spirit to turn challenges into opportunities. Together, we can shape the future of the industry through innovation that matters.